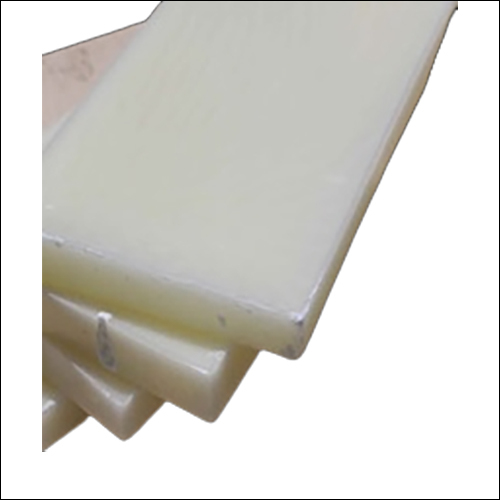

HDPE Wax

HDPE Wax Specification

- Molecular Formula

- (C2H4)n

- Viscosity

- 10 15 cps at 140C

- Density

- 0.97 Gram per cubic centimeter(g/cm3)

- Storage

- Store in dry, cool, and ventilated area away from direct sunlight

- Application

- Plastic processing, master batches, PVC, rubber, adhesives, and ink industries

- Form

- Powder or Granules

- Melting Point

- 105C 115C

- Oil Content %

- < 0.5%

- Refinement

- Highly Refined

- Crystalline Index

- > 95%

- Scale of Deoiling

- 99%

About HDPE Wax

By incorporating market procedures of organizational insight in our production process, we are able to manufacture and supply HDPE Wax. These products are popularly known in the market as polythylene wax that is widely used in different industries as a lubricating agent. Our clients applaud these products for their pure nature and good thermal stability. HDPE Wax is available with us in different quantities as per the demands of the clients.

Other details:

| No. | Properties | Value |

| 1 | Drop Melting Point | 100-120 |

| 2 | Needle Penetration 25C (ASTM D 1321) | 25-45 |

| 3 | Viscosity at 149 C | 20-40 |

Applications:

- Used in Ink & Paint additive

- Rubber sole additive

- Coating

Versatile Applications Across Industries

HDPE Wax stands out for its adaptability in various sectors, including plastics, rubbers, adhesives, and printing inks. Its low oil content, high crystalline index, and impressive refinement ensure compatibility with master batches, PVC compounds, and more. From improving product texture to enhancing processing efficiency, HDPE Wax delivers reliable results for manufacturers, exporters, and suppliers across India.

Superior Technical Properties

Manufactured to offer a high melting point and excellent purity, HDPE Waxs formeither as powder or granulesgives users manufacturing flexibility. Its stable molecular structure (C2H4)n and a density of 0.97 g/cm ensure it integrates seamlessly into a range of formulations. The waxs viscosity of 1015 cps at 140C supports even distribution, contributing to improved processing and product performance.

FAQs of HDPE Wax:

Q: How is HDPE Wax used in plastic processing and master batch manufacturing?

A: HDPE Wax is incorporated during the blending and extrusion of plastic materials or master batches to serve as a lubricant and dispersing agent. This helps improve flow characteristics and overall surface finish of the final product, ensuring more uniform coloration and texture during processing.Q: What benefits does highly refined HDPE Wax offer to the PVC and rubber industries?

A: Its highly refined nature, with low oil content and a crystalline index above 95%, enhances processing stability and reduces potential for contamination. In PVC and rubber formulations, HDPE Wax acts as a processing aid, promoting better release, increased flexibility, and a smoother final surface.Q: When should HDPE Wax be added during the production process?

A: HDPE Wax is generally introduced at the compounding or blending stage. Whether working with plastics, rubber, or adhesives, adding the wax early in the process ensures even distribution and optimal performance in the end product.Q: Where should HDPE Wax be stored to maintain its quality?

A: To preserve its properties, HDPE Wax should be stored in a dry, cool, and well-ventilated area, away from direct sunlight. Proper storage conditions help prevent moisture absorption and degradation of the waxs chemical structure.Q: What is the recommended process for handling and using HDPE Wax?

A: When using HDPE Wax in powder or granule form, ensure that it is measured and blended accurately according to your specific formulation. Mechanical mixing or extrusion is typically employed, and the wax should be thoroughly incorporated for uniform effects.Q: What advantages does HDPE Wax offer for adhesive and ink production?

A: In adhesives and inks, HDPE Wax improves viscosity control, compatibility, and oxidative stability. Its high purity and deoiled content prevent unwanted interactions, while its molecular structure facilitates even dispersion, promoting a smooth, consistent finish.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paraffin Wax Category

Fully Refined Paraffin Wax

Price 140 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Application : Other, Candle Making, Waterproofing, Cosmetics, Food Packaging, Rubber, Pharmaceuticals, Crayons

Refinement : Fully Refined

Form : Other, Solid (Slabs or Granules)

Liquid Paraffin Wax

Price 47 INR / Liter

Minimum Order Quantity : 1000 Liters

Application : Other, Cosmetics, Pharmaceuticals, Polishing, Candle Making, Lubricants, Textile, Paper, and Rubber industries

Refinement : Fully Refined

Form : Liquid

Micro Wax

Application : Other, Rubber, Adhesives, Plastic, Paper, Cosmetics, Pharmaceuticals

Refinement : Other, Highly Refined

Form : Solid

Residue Wax

Price Range 80.00 - 115.00 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Application : Candle Making

Refinement : Fully Refined

Form : Solid

Send Inquiry

Send Inquiry