Microcrystalline Wax

Microcrystalline Wax Specification

- Molecular Formula

- CnH2n+2

- Application

- Polishes, Cosmetics, Adhesives, Rubber Industry, Pharmaceuticals

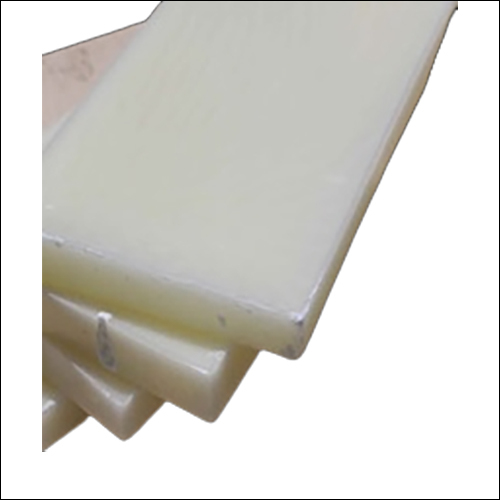

- Form

- Solid

- Oil Content %

- 3.5%

- Refinement

- Fully Refined

- Crystalline Index

- Fine

- Scale of Deoiling

- High

About Microcrystalline Wax

Incorporating modern technology with developed equipment, we are able to manufacture and supply Micro-Crystalline Wax. These products are used in applications related to adhesives, tire & rubber, castings, candles, cosmetics and corrugated boards. Our offered products are also used custom making of varied kinds of small sculptures and jewelry. Varied industries also use these products for modifying the basic crystalline properties of paraffin wax. Microcrystalline wax is delivered to the clients in an allotted time frame owing to our expert delivery team.

Other details:

| No. | Properties | Values |

| 1 | Drop Melting Point, c. | 65.5 & 76.6 |

| 2 | Oil Content | 10.0 Max |

| 3 | Penetration Number @ 25 c.100 g. 5 Sec | 100 Max |

| 4 | Color | White |

Application :

- Base for chewing gum, lipstick, cold creams, ointments where they

- Harden, lubricate, carry additives, and protect against moisture

- Food packaging, protecting against moisture through wax impregnated

- Paper, film, foil and corrugated board

- increasing the fluidity and the flexible bonding of hot-melt adhesives

- Crayons, candles and caulk to sealants and fine polishes

- Host for compounds that prevent rust

- Insulating materials

Versatility Across Industries

Microcrystalline Wax is sought after for its adaptability in multiple sectors, including cosmetics, pharmaceutical formulations, adhesives, rubber compounding, and surface polishes. Its unique properties like fineness and high scale of deoiling make it exceptionally suited for applications where purity, flexibility, and texture enhancement are crucial.

Fully Refined for Maximum Performance

The thorough refining process ensures that Microcrystalline Wax maintains a low oil content and a fine crystalline index. This not only offers optimized stability and consistency but also enhances its barrier properties and compatibility in complex formulations, making it a preferred choice for demanding industrial and consumer products.

FAQs of Microcrystalline Wax:

Q: How is Microcrystalline Wax produced and refined for industrial applications?

A: Microcrystalline Wax is produced during the refining of petroleum, followed by comprehensive deoiling and purification processes. This results in a fully refined wax characterized by a fine crystalline structure and very low oil content, making it ideal for use in sensitive applications like cosmetics and pharmaceuticals.Q: What benefits does Microcrystalline Wax offer over regular paraffin wax?

A: Compared to regular paraffin wax, Microcrystalline Wax provides greater flexibility, superior binding ability, and better adhesive properties. Its fine crystalline structure enhances its use in polishes, rubber, and adhesive applications while offering a smoother texture for cosmetic formulations.Q: When should Microcrystalline Wax be used in the pharmaceutical industry?

A: Microcrystalline Wax is incorporated in pharmaceuticals when moisture resistance, texture control, or emollient properties are required. Its purity and inert nature make it suitable for topical ointments, tablet coatings, and controlled-release drug delivery systems.Q: Where can reliable suppliers and distributors of Microcrystalline Wax be found in India?

A: Microcrystalline Wax is widely available across India through reputable distributors, exporters, importers, manufacturers, suppliers, traders, and wholesalers. Selecting a vendor with extensive experience and a focus on quality assurance ensures reliable and consistent supply for industrial needs.Q: What is the recommended process for using Microcrystalline Wax in cosmetics and adhesives?

A: When using Microcrystalline Wax in cosmetics or adhesives, it is typically melted and blended with other ingredients under controlled conditions. Its compatibility and uniform melting enable smooth integration into formulations, resulting in enhanced texture, stability, and performance of the final product.Q: How does the high scale of deoiling in Microcrystalline Wax improve its usability?

A: A high scale of deoiling means most oil impurities are removed, resulting in a purer wax with improved performance characteristics such as higher melting point, better plasticity, and increased shelf stability. This makes it excellent for use in demanding applications across various industries.Q: What are the key usage benefits for rubber and polish industries?

A: Microcrystalline Wax improves the workability and elasticity in rubber manufacturing, while providing gloss, water resistance, and durability in polishes. Its refined properties ensure excellent dispersion and adherence, adding functional value to finished goods in both sectors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paraffin Wax Category

Liquid Paraffin Wax

Price 47 INR / Liter

Minimum Order Quantity : 1000 Liters

Refinement : Fully Refined

Application : Other, Cosmetics, Pharmaceuticals, Polishing, Candle Making, Lubricants, Textile, Paper, and Rubber industries

Form : Liquid

Scale of Deoiling : High Degree

Fully Refined Paraffin Wax

Price 140 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Refinement : Fully Refined

Application : Other, Candle Making, Waterproofing, Cosmetics, Food Packaging, Rubber, Pharmaceuticals, Crayons

Form : Other, Solid (Slabs or Granules)

Scale of Deoiling : 99.5%

Micro Wax

Refinement : Other, Highly Refined

Application : Other, Rubber, Adhesives, Plastic, Paper, Cosmetics, Pharmaceuticals

Form : Solid

Scale of Deoiling : Fully Deoiled

Residue Wax

Minimum Order Quantity : 25 Kilograms

Refinement : Fully Refined

Application : Candle Making

Form : Solid

Send Inquiry

Send Inquiry